BENEFITS OF WORKING WITH US

Certification

EN ISO 9001

Quality management system for the production is in accordance with EN ISO 9001

EN ISO 14001

Since 2015, the system for environmental management under EN ISO 14001 was introduced in our Company.

How we work

01

PLANNING AND PREPARATION

Determining technical requirements and drawings for producing workpieces

02

PREPARATION OF RAW MATERIALS

Aluminum alloys quality assessment and preparation for usage

03

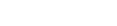

MACHINING OF THE MATERIAL

Casting, bending, pressing, turning and other material processing operations

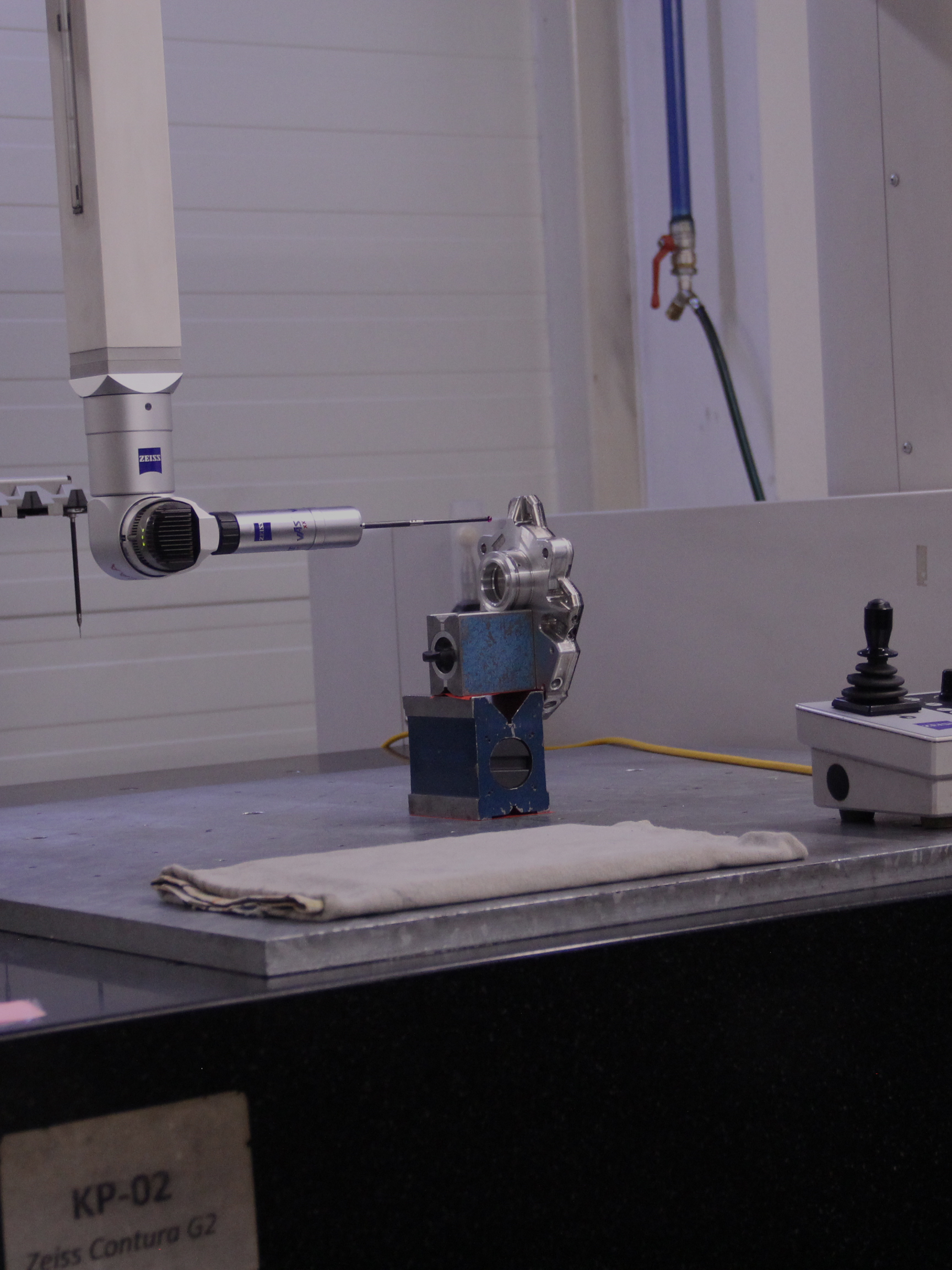

04

QUALITY CONTROL

Workpieces testing and inspecting to ensure they comply with technical requirements

05

PACKAGING AND DELIVERY

Product packaging and delivery to the client

Our clients

About which we can tell

Our cases

Contact us

And our managers will provide advice specifically at your request

Or write to us

Your message has been successfully sent

If you still have questions, you can write a letter to our email address

Your message has been successfully sent

If you still have questions, you can write a letter to our email address

Contact us

And our managers will give advice specifically at your request

Add review

Your review will be added after moderation