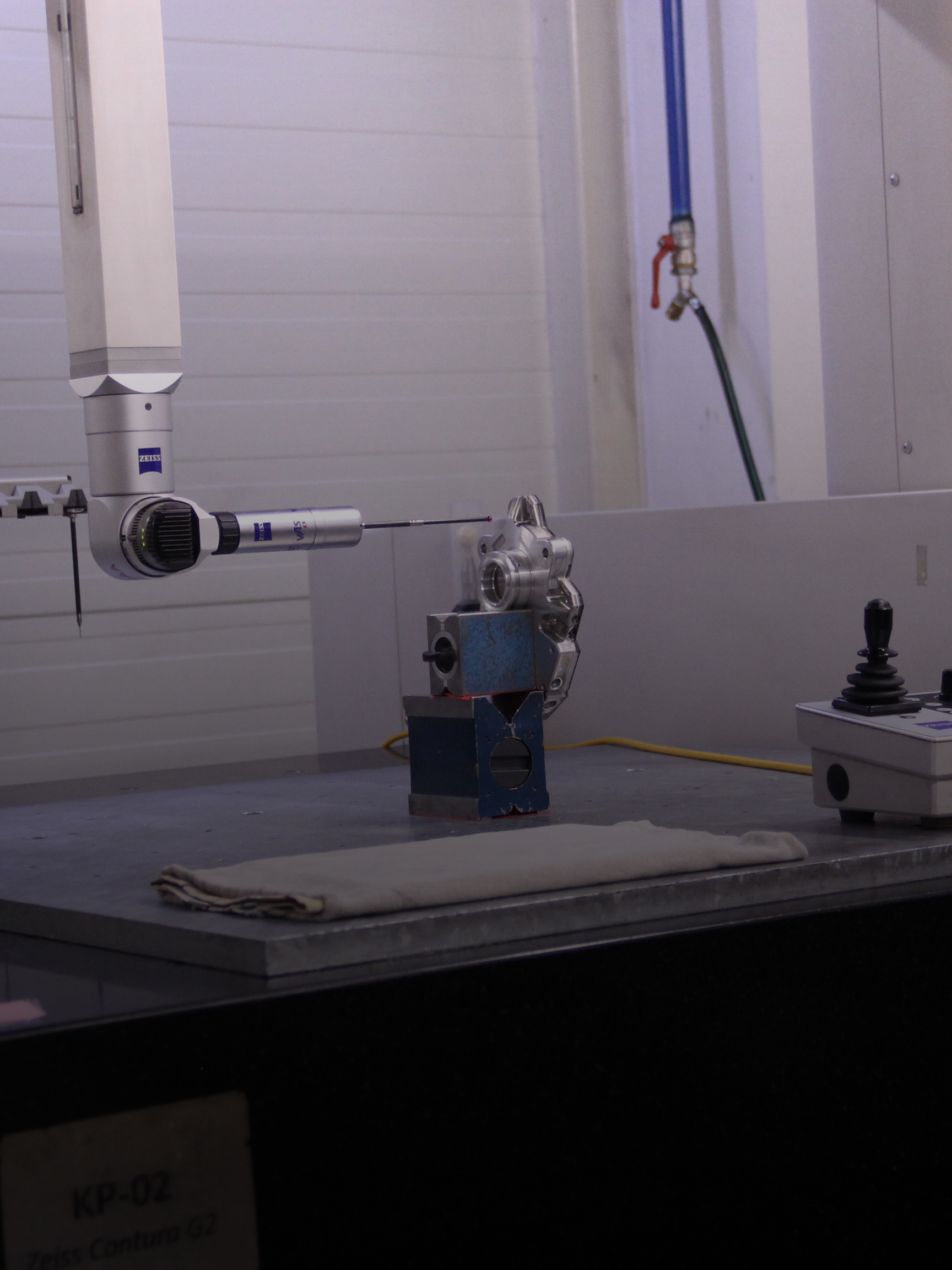

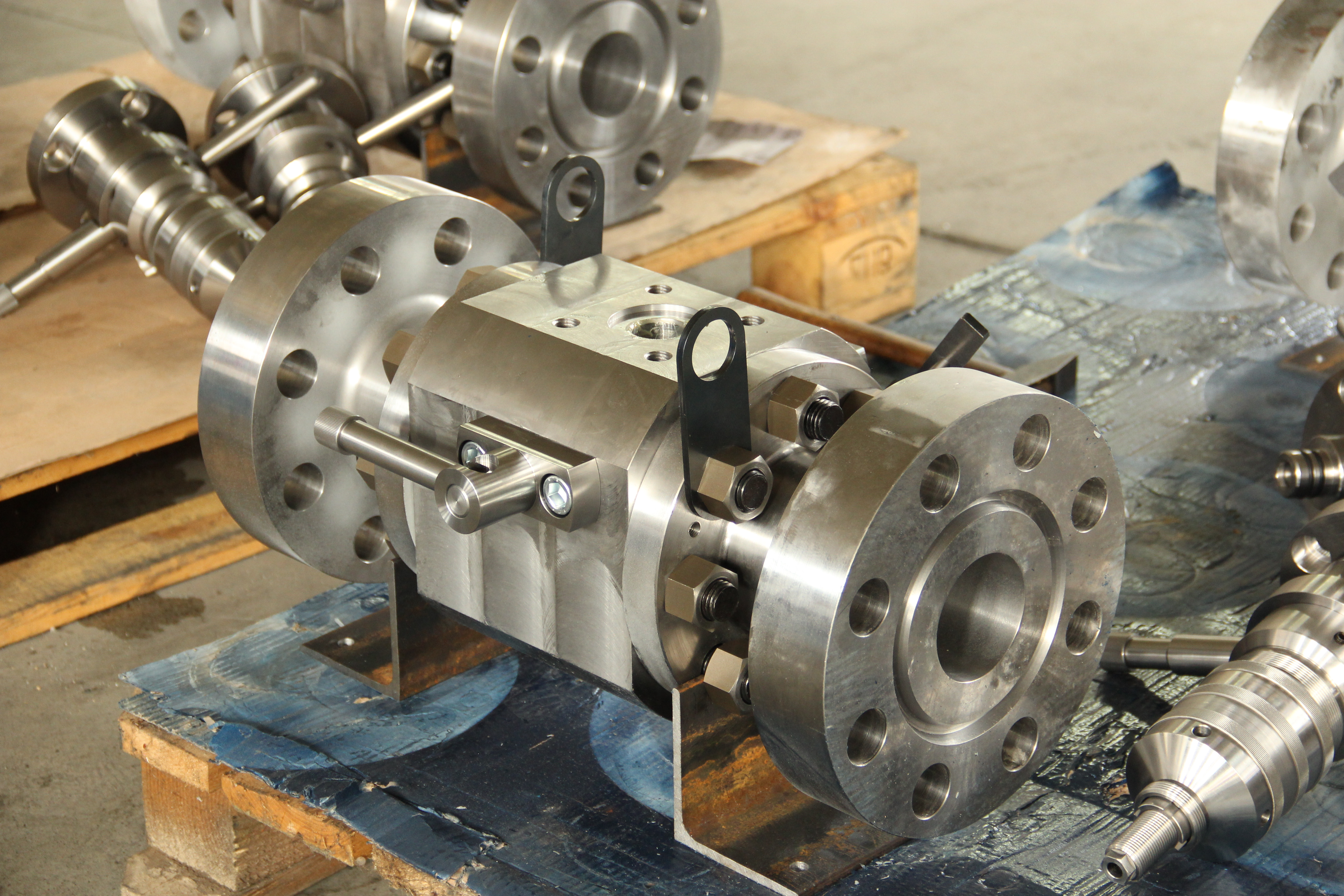

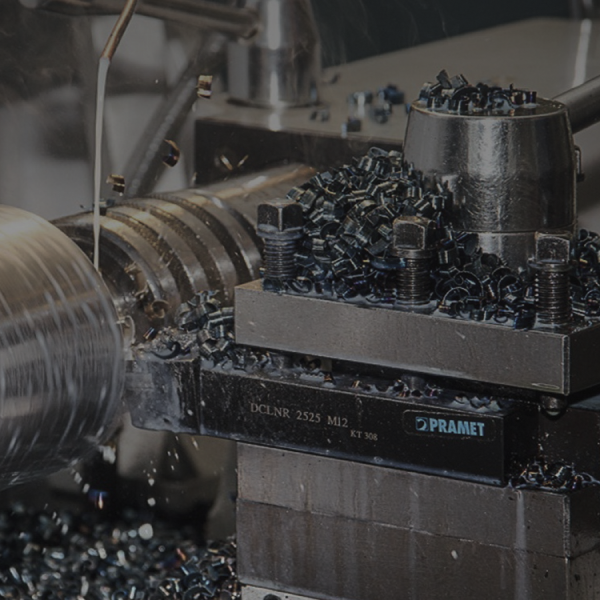

With 10 years of experience in the metalworking industry, we offer a complete range of services for metal machining, including milling and turning.

We use modern software and high-tech equipment for the provision of quality services to our clients within reasonable deadlines and at competitive prices. We produce both simple and complex turning components for a wide range of industries.

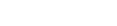

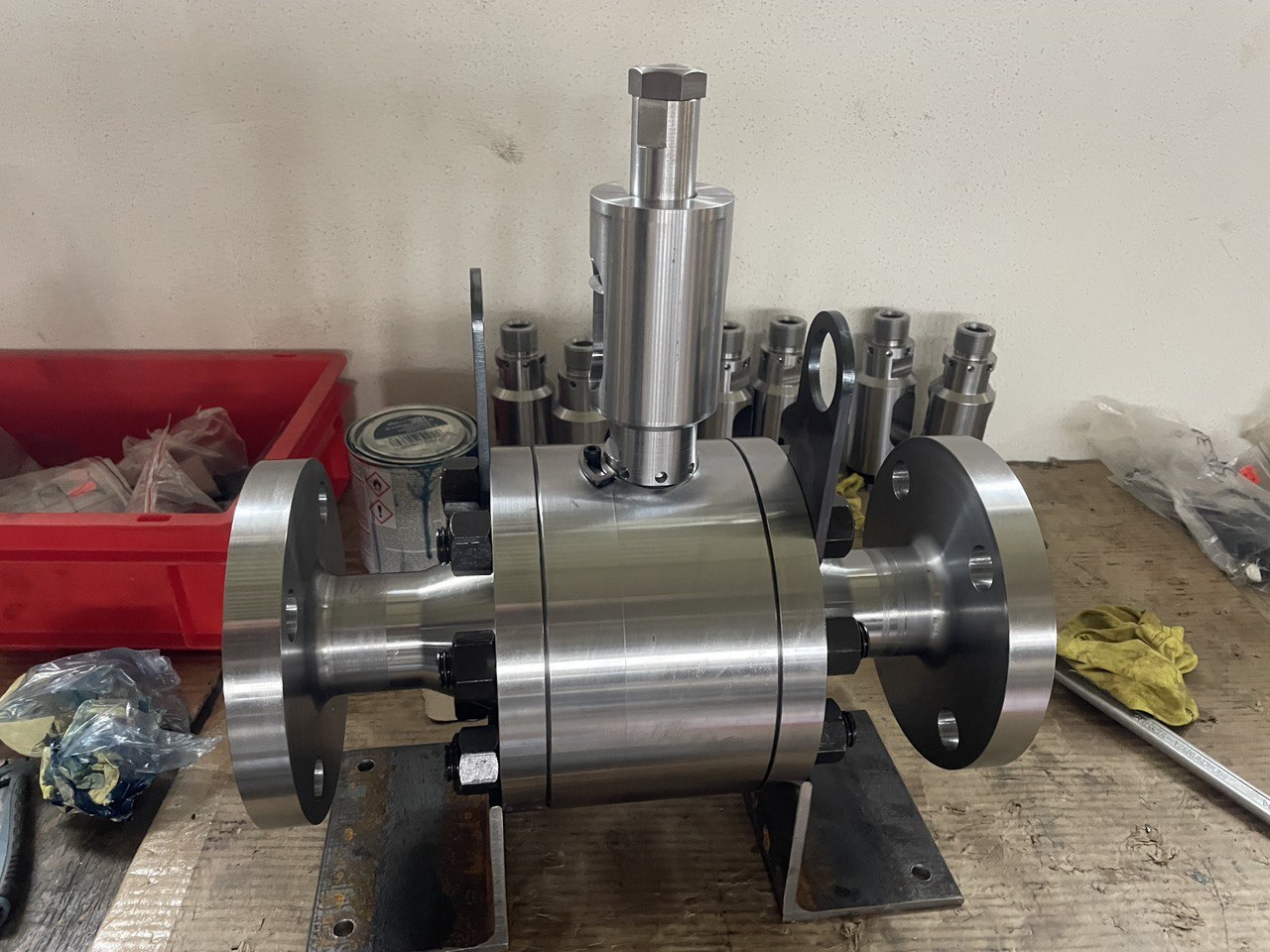

Every year, the Company produces thousands of different parts, which, combined with our in-house technological base, provide the opportunity for prompt development and launch of new projects. The Company has experience of metal and composite metal units and parts production for various industries.

Our MPSR Company produces screw loaders and we have been ordering parts for them from TOOLSHED for 3 years already. All parts are of the highest quality, which ensures the durability of our products. We enjoy working with TOOLSHED as they cover the whole complex of our needs.

We’ve addressed Toolshed Company with the need to produce aluminum fasteners for a new model of local purification device. All production stages were with minimal engagement from our side and within the agreed deadline. We are still cooperating with the Company.

And our managers will provide consultation specifically to your request.

And our managers will give advice specifically at your request

Your review will be added after moderation